Molds and coatings for the bakery industry

As a company of molds and coatings, REKLIN uses quality industrial non-stick material, with different thicknesses and qualities. We adapt to each project and offer the most suitable type of non-stick coating in each case.

Molds for bakery

The molds for industrial bakeries that we design and manufacture at REKLIN withstand sudden temperature changes, facilitate demolding and are highly efficient since they allow a high number of baking batches.

With our catalog we offer savings, productivity and quality to the bakery industry and bakery businesses. We analyze and study each customer to offer the most suitable baking pan and non-stick coating for their specific case and the type of product to be baked.

Opt for excellence and lifelong flavor in your bakery products.

Molds and coatings for bakery industry

We manufacture molds for hamburger bread and sliced bread in different sizes and shapes. All of them are made with quality materials, resistant to high temperatures and sudden temperature changes.

These breads can be made with a wide variety of ingredients, thus achieving a variety of types (white bread, whole wheat bread, bread with seeds…), so bread baking pans are key to achieve quality products, with a uniform size and shape and optimal demolding.

Bakery molds and bakery molds

We also have molds for bakery and pastry of different measures, sizes and shapes for sweet and savory pastries, different types of breads… We adapt to the needs of each customer, their baking capacity, the type of product and their demand.

We offer trays and molds for industrial bakeries and pastry shops so you can produce in large quantities, quickly and without waste. Prepare delicious loaves of bread, croissants, biscuits, muffins, napolitanas and much more.

Advantages of non-stick baking pans for industrial bakeries

All types of baking pans in our catalog have a non-stick coating, so they are non-stick, ideal for industrial bakery and pastry stores. In addition, choosing them means advantages such as:

Perfect demolding without waste

Easy to clean .

Food safety and hygiene.

They support a large number of baking cycles.

They allow a uniform and homogeneous baking.

Improve the appearance of the product.

They reduce waste of the masses.

They increase the speed of production.

They are resistant and durable.

The use of oils and release agents is reduced.

They enable more sustainable and efficient baking .

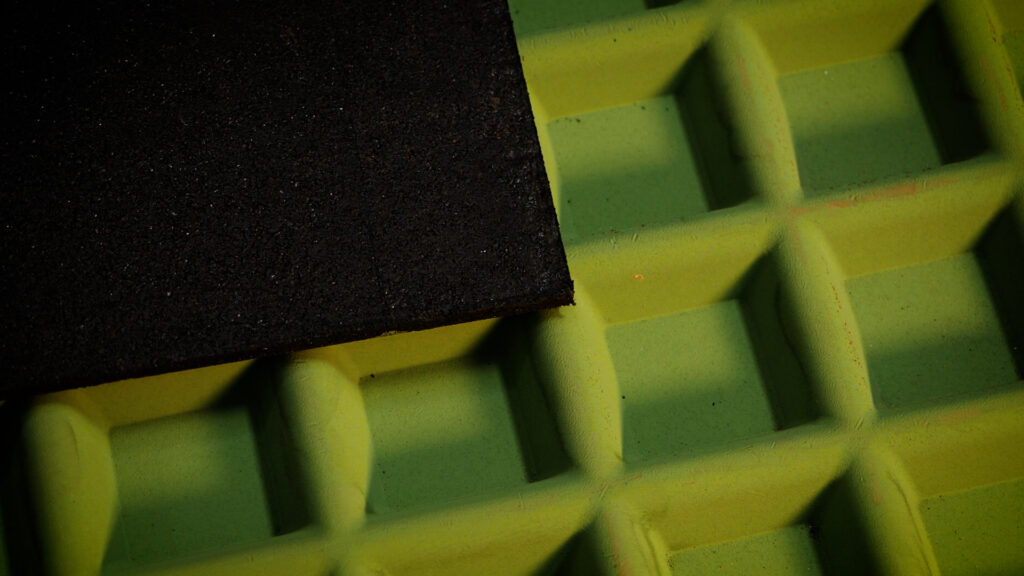

Anti-adhesive coatings for bakery molds

The bakery molds we design have non-stick and non-adhesive coatings that prevent food, dough, pasta and liquids from sticking to the trays. At the same time, they allow a quality demolding, without waste and without the need to use oils for this purpose.

The PFA coating we use is food grade and regulated for use in contact with food. They facilitate the entire baking and demolding process of industrial and modern bakery products.

- Non-stick

- Resistant to heavy use

- Resistant to high temperatures

- Antifriction

- Easy to clean

- Low friction capacity

Benefits of antiadhesive coatings in molds

Using this type of Teflon coating gives it inert properties (it does not react on contact with other chemical substances), non-stick and impermeable, which facilitates precise, fast and easy-to-clean demolding. It is also resistant to high temperatures and sudden changes in temperature.

In REKLIN we study each project and advise our customers to choose the best type of coating according to their needs and budget. Therefore, we have different types of Teflon coating. We advise each customer to choose the most suitable for their project.

Solutions for the Bakery Industry

Invest in a REKLIN baking pan for sliced bread, toasted bread, hamburger bread, loaves, pastries, cakes and all types of industrial bakery products and guarantee quality, uniform and precise baking.

We develop baking and industrial bakery molds specifically for high production volumes, thus guaranteeing a homogeneous baking, a perfect and fast demolding, and a greater durability of the trays, thus achieving a greater number of baking cycles.

And not only that, we also repair the trays and supports so that you can continue using them efficiently without having to invest in new material.

We make the modern efficient bakery possible, with uniform, homogeneous products with an unmatched taste.